Ipuleti lensimbi eliphehliwe

Ukuhlukaniswa nokusetshenziswa

Ngokwezindlela zokukhiqiza nezokucubungula, ingahlukaniswa ngezigaba ezilandelayo:

1.I-alloyed steel galvanized plate. Lolu hlobo lwepuleti lensimbi lwenziwa futhi ngendlela ye-hot-dip, kodwa lushiswa ku-alloy coating ye-zinc futhi insimbi yakheka cishe ku-50O ℃. Leli shidi elinothayela linobulili obuhle bokunamathela kanye nokushisela.

2.Ipuleti lensimbi elinothayela oshisayo. Gxilisa i-steel plate ku-molten Duo groove ukuze ulenze linamathele kungqimba lwe-Duo steel plate.

Njengamanje, ikhiqizwa ikakhulukazi inqubo eqhubekayo yokufaka ama-galvanizing, okungukuthi, ipuleti lensimbi eligoqiwe licwiliswa ngokuqhubekayo kubhavu lokucwenga le-zinc elincibilikisiwe ukwenza ipuleti lensimbi.

3.Electrogalvanized steel plate. Ishidi lensimbi elakhiwe ngendlela ye-electroplating linokusebenza okuhle. Kodwa-ke, ukugqoka kuncane futhi ukumelana nokugqwala akukuhle njengalokho kweshidi elifakwe emanzini ashisayo; ④ Ingxubevange nepuleti lensimbi eliyinhlanganisela. Kuyipuleti lensimbi elenziwe nge-zinc nezinye izinsimbi ezinjengomthofu ne-zinc. Lolu hlobo lwepuleti yensimbi alugcini nje ngokusebenza kahle kakhulu kwe-anti-rust, kodwa futhi lunomsebenzi omuhle wokumboza.

4.Ipuleti lensimbi eliwuthayela elinohlangothi olulodwa kanye nepuleti lensimbi enamacele amabili elihlukene elinezinhlangothi ezimbili, okungukuthi, imikhiqizo enamakhanga ohlangothini olulodwa kuphela. Ikwazi ukuzivumelanisa nezimo kangcono kuneshidi elinamaceleni amabili elinothayela ekushiseleleni amalahle, ukunamathela, ukwelashwa okulwa nokugqwala, ukucutshungulwa, njll. Ukuze unqobe ubungozi bokungagqoki i-zinc ngakolunye uhlangothi, kunolunye uhlobo lweshidi likathayela elimbozwe ungqimba oluncane lwezinc ngakolunye uhlangothi, okungukuthi, ishidi le-zinc eliphindwe kabili futhi elihlukile.

5.I-alloy kanye ne-composite steel galvanized plate. Kuyipuleti yensimbi eyenziwe nge-zinc nezinye izinsimbi ezifana ne-aluminium, i-lead, i-zinc, njll. Lolu hlobo lwe-steel plate alugcini nje ngokusebenza okuhle kakhulu kokulwa nokugqwala, kodwa futhi lunomsebenzi omuhle wokumboza.

Ngaphezu kwalezi zinhlobo ezinhlanu ezingenhla, kukhona ipuleti lensimbi elinombala, ipuleti lensimbi yokuphrinta enamapulangwe, ipuleti lensimbi elakhiwe nge-PVC elaminethiwe, njll.

Ukubukeka

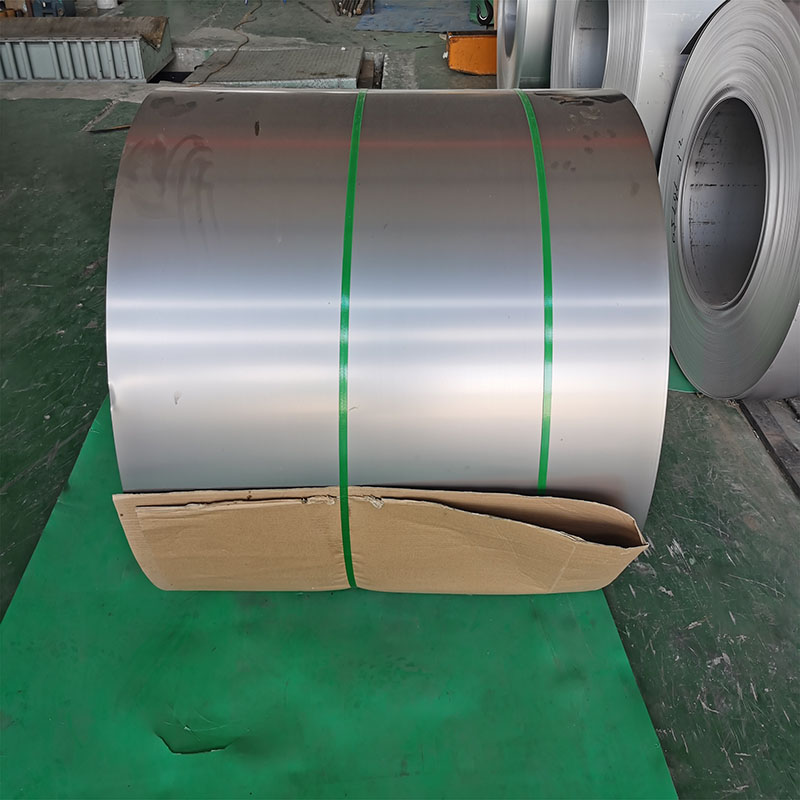

1. Ukupakisha

Ingahlukaniswa ngezinhlobo ezimbili: ishidi likathayela elisikwe libe ubude obungaguquki kanye neshidi likathayela ngekhoyili. Ukupakishwa kweshidi lensimbi okujwayelekile kuvalwe ngephepha elivikela umswakama, kanti ingaphandle liboshwe ngokhalo lwensimbi, eliboshelwe ngokuqinile ukuze kuvinjwe ishidi elingaphakathi likathayela ukuthi lingakhuhlani.

2. Ukucaciswa nosayizi

Ubukhulu bomkhiqizo obufanele (njengalokhu okulandelayo futhi) bhala izilinganiso ezinconyiwe, ukujiya, ubude nobubanzi beshidi likathayela kanye nokulimala kwalo okuvunyelwe. Ngaphezu kwalokho, ububanzi nobude bebhodi kanye nobubanzi bomqulu kungabuye kunqunywe ngokuvumelana nesicelo somsebenzisi.

3. Ubuso

Isimo esijwayelekile: ngenxa yezindlela zokwelashwa ezihlukene enqubweni yokumboza, isimo esijwayelekile seshidi likathayela sihlukile, njengesimo esijwayelekile se-zinc flake, i-zinc flake enhle, i-zinc flake, i-zinc-free flake kanye nokwelashwa kwe-phosphating. Ishidi eliwuthayela kanye nekhoyili elisikwe libe ubude obunqunyiwe akufanele libe nokukhubazeka okuthinta ukusetshenziswa (njengoba kuchazwe ngezansi), kodwa ikhoyili kufanele ivunyelwe ukuthi ibe nezingxenye zokushisela nezinye ezingakhubazekile.

4. Ubuningi be-galvanizing

Inani lesikali lobuningi obufaka uthayela: ubuningi bokwenza uthayela kuyindlela eyamukelwa kabanzi futhi ewusizo ukukhombisa ukujiya kwezinki enamathela eshidini likathayela. Kunezinhlobo ezimbili ze-zinc plating: inani elifanayo le-zinc plating nhlangothi zombili (okungukuthi ugqinsi olulinganayo lwe-zinc plating) kanye nenani elihlukile le-zinc plating nhlangothi zombili (okungukuthi ukuhlukaniswa kwe-zinc plating). Iyunithi yobuningi bokwenza uthayela ngu-g/m.

5. Umsebenzi womshini

(1) Ukuhlolwa kwe-tensile: ngokujwayelekile, inqobo nje uma ishidi elinothayela lesakhiwo, umdwebo nomdwebo ojulile linezidingo zokusebenza eziqinile.

(2) Ukuhlola ukugoba: Kuyigama elibalulekile ukukala umsebenzi wezobuchwepheshe wepuleti elincanyana. Kodwa-ke, izidingo zamazwe ahlukene zezinhlobo ezahlukene zeshidi elinamapulangwe zihlukile ngempela. Ngokuvamile, ngemva kokuba ishidi eliphehliwe ligotshwe ngo-180 °, ungqimba lwezinc ngeke lushiye iphrofayili yangaphandle, futhi isisekelo seshidi ngeke siqhekeke noma siphuke.

Izici zepuleti lensimbi enama-galvanized: ukwenza uthayela kungavimbela ngempumelelo ukugqwala kwensimbi futhi kwandise impilo yesevisi. Ishidi lensimbi elakhiwe (ukujiya okungu-0.4 ~ 1.2mm) libizwa nangokuthi ishidi lensimbi elinamandla, elivame ukubizwa ngokuthi ishidi lensimbi elimhlophe. Ishidi lensimbi eliphehliwe lisetshenziswa kabanzi ekwakhiweni, ezimotweni, ezintweni zikagesi zasendlini, izidingo zansuku zonke kanye nezinye izimboni.

Usayizi: ngokuya ngezidingo zekhasimende, ubude nobubanzi bungenziwa isicaba noma ngokwezifiso.

Isimo esingaphezulu: Ngenxa yezindlela zokwelashwa ezihlukene enqubweni yokumboza, isimo esingaphezulu seshidi likathayela sihlukile, njenge-zinc flake evamile, i-zinc flake enhle, i-zinc flake, i-non-zinc flake kanye ne-phosphating surface. Izinga lesiJalimane liphinde licacise ibanga elingaphezulu.

Ishidi elinothayela lizoba nokubukeka okuhle futhi ngeke libe nokukhubazeka okulimazayo ekusetshenzisweni komkhiqizo, okufana nokungacwebeki, izimbobo, imifantu, uqweqwe, ukushuba okungaphezulu kwe-plating, imihuzuko, ukungcola kwe-chromic acid, ukugqwala okumhlophe, njll. Izindinganiso zakwamanye amazwe azicaci kahle mayelana nokukhubazeka okuthile kokubukeka. Ezinye iziphambeko ezithile zizofakwa ohlwini lwenkontileka lapho ku-oda.

Izakhiwo Zemishini

Ukuhlolwa kwe-tensile:

1.Inkomba yokusebenza: Ngokuvamile, ishidi elithayelayo kuphela lesakhiwo, umdwebo nomdwebo ojulile onezidingo zesakhiwo esiqinile. Ishidi likathayela lesakhiwo lizoba nephuzu lokuthela, amandla aqinile kanye nobude; Ukwelula kuphela kuyadingeka ukuze welule. Bona izilinganiso zomkhiqizo ezifanele kokuthi "8" salesi sigaba ngamavelu athile.

2.Indlela yokuhlola: iyafana nendlela yokuhlola yeshidi lensimbi elivamile, bheka izindinganiso ezifanele ezinikezwe kokuthi "8" kanye nezindinganiso zendlela yokuhlola ezisohlwini lwe-"Ordinary carbon steel sheet".

Ukuhlolwa kokugoqa:

Ukuhlola ukugoba kuyinto eyinhloko yokulinganisa ukusebenza kobuchwepheshe kweshidi, kodwa izimfuneko zezindinganiso zikazwelonke ezihlukahlukene kumashidi ahlukahlukene anamathani azihambisani. Amazinga aseMelika awadingi ukuhlolwa kokugoba nokuqinile ngaphandle kwebanga lesakhiwo. E-Japan, ukuhlolwa kokugoba kuyadingeka ngaphandle kwamapuleti esakhiwo, wezakhiwo kanye nawojwayelekile.

Izimfuneko: ngokuvamile, ngemva kokuba ishidi lika-galvanized ligotshwe ngo-180 °, akumele kube nokuhlukaniswa kwengqimba ye-zinc endaweni engaphandle, futhi akumele kube nokuqhekeka nokuphuka esisekelweni sepuleti.

Izici nokusebenza

Umbala wepuleti lensimbi umkhiqizo owenziwe ngepuleti lensimbi eligoqiwe elibandayo, ipuleti lensimbi, elihlanganiswe (elifakwe umqulu) noma ifilimu eyinhlanganisela yezinto eziphilayo (ifilimu ye-PVC, njll.) ngemva kokwelashwa ngamakhemikhali ngaphezulu, bese ibhakwa futhi ilapheka. Abanye abantu baphinde babize lo mkhiqizo ngokuthi "i-roller coated steel plate", "plastic color steel plate". Imikhiqizo yamapuleti ombala igoqwa abakhiqizi emigqeni yokukhiqiza eqhubekayo, ngakho-ke ibizwa nangokuthi ama-roll coated steel plate rolls. Ipuleti lensimbi lombala alinawo amandla aphezulu emishini yensimbi nensimbi, kulula ukwenza ukusebenza, kodwa futhi nezinto ezinhle zokuhlobisa zokuhlobisa kanye nokumelana nokugqwala. Ipuleti lensimbi lombala liyinto entsha emhlabeni wanamuhla. Ngokuthuthuka kwesayensi nobuchwepheshe, ukuthuthukiswa kokuqwashisa ngemvelo, ukuthuthukiswa kwamazinga okuphila kwabantu, izindlu eziphathwayo zensimbi enombala zikhombisa amandla aqinile namathemba emakethe abanzi, ngokwakhiwa, izinto zikagesi zasendlini, ezomshini nogesi, ezokuthutha, umhlobiso wangaphakathi, izinto zikagesi zasehhovisi nezinye izimboni ezithandwayo.

Izinga Lomkhiqizo

I-JIS G3302-94 ishidi lensimbi;

I-JIS G3312-94 ishidi lensimbi elipendiwe;

I-JIS G3313-90 (96) Ishidi lensimbi elenziwe nge-electrogalvanized; Izidingo ezijwayelekile zeshidi lensimbi elicwebezelayo elishisayo;

I-ASTM A526-90 ishidi lensimbi eshisiwe yediphu elishisayo;

I-ASTMA 527-90 (75) ivalwe ishidi lensimbi elicwebezelayo elishisayo;

I-ASTMA528-90 ishidi lensimbi elakhiwe ngokujulile elidonswe ngokujulile; Ishidi lensimbi elishisayo lokucwilisa uphahla nodonga;

I-ASTMA44-89 Ishidi lensimbi elidiphu elishisayo lemisele;

I-ASTM A446-93 ishidi lensimbi elakhiwe ngensimbi eshisayo ediphu elishisayo;

I-ASTMA59-92 ishidi lensimbi eligoqiwe elibandayo;

I-ASTMA642-90 ishidi lensimbi elicwebezelayo elicwebezelayo elishisayo elishisayo;

Γ OCT7118-78 ishidi lensimbi;

I-DINEN10142-91 Ingxenye 1 Insimbi ephansi ene-carbon steel hot-dip galvanized steel strip kanye ne-steel plate;

I-DIN1012-92 ingxenye ye-2 ishidi lensimbi elishisayo elishisayo.

Izinga Lokuhlola

I-JIS H0401-83 Indlela yokuhlola ye-hot-dip galvanizing;

I-DIN50952-69 Indlela yokuhlola ye-hot-dip galvanizing.

Ithagethi

Imikhiqizo enamashidi nama-strip steel isetshenziswa kakhulu kwezokwakha, embonini ekhanyayo, ezimoto, ezolimo, ezemfuyo, ezokudoba, ezentengiselwano nakwezinye izimboni. Imboni yezokwakha isetshenziselwa ikakhulukazi ukwakha amaphaneli ophahleni lwezakhiwo ezilwa nokugqwala, ama-roof grids, njll; Imboni yokukhanya iyisebenzisela ukwenza amagobolondo ezinto zikagesi zasendlini, oshimula bomphakathi, izitsha zasekhishini, njll., futhi imboni yezimoto iyisebenzisela kakhulu ukwakha izingxenye zezimoto ezimelana nokugqwala, njll; Ezolimo, ukufuywa kwezilwane kanye nezokudoba kusetshenziswa kakhulu njengendawo yokugcina ukudla kanye nokuthutha, amathuluzi okucubungula eqandisiwe enyama nemikhiqizo yasemanzini, njll; I-Commerce isetshenziswa kakhulu njengokugcinwa nokuthuthwa kwezinto zokwakha, amathuluzi okupakisha, njll.