Inani elikhulu lezinqwaba zamashidi ensimbi ezenziwe ngokwezifiso abakhiqizi abakhethekile

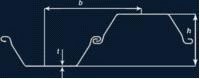

Isakhiwo Sephrofayela

Inqwaba yeshidi lensimbi i-cofferdam iyona esetshenziswa kakhulu. Inqwaba yeshidi lensimbi iwuhlobo lwensimbi yesigaba enomlomo ovalayo. Ingxenye yayo ihlanganisa ipuleti eliqondile, i-slot kanye ne-Z shape, futhi inosayizi abahlukahlukene namafomu ahlanganisiwe. Ezivamile isitayela Larsen, Lavanna isitayela, njll.

Izinzuzo zayo yilezi: amandla aphezulu, kulula ukushayela ungqimba lwenhlabathi eqinile; Ukwakhiwa kungenziwa emanzini ajulile, futhi ukusekelwa okuthambekele kunganezelwa ukwakha ikheji uma kunesidingo. Ukusebenza okuhle okungangeni manzi; Ingenza ama-cofferdams anomumo ohlukahlukene njengoba kudingeka futhi ingasetshenziswa kabusha izikhathi eziningi. Ngakho-ke, isetshenziswa kabanzi.

I-Cofferdam phezulu kwe-caisson evulekile ivame ukusetshenziswa ekwakhiweni kwebhuloho, futhi isetshenziswa kakhulu. I-Cofferdam yesisekelo sekholomu yamapayipi, isisekelo senqwaba kanye nesisekelo esisikiwe esivulekile, njll.

Lawa ma-cofferdam ngokuvamile awuhlobo oluvalwe ngodonga olulodwa. Kukhona ukusekela okuqondile nokuvundlile kuma-cofferdams. Uma kunesidingo, izisekelo ze-oblique zengezwa ukwenza i-cofferdam. Isibonelo, isisekelo sekholomu yepayipi yebhuloho lomfula i-Yangtze e-Nanjing, e-China, lalivame ukusebenzisa i-cofferdam eyindilinga yeshidi lensimbi enobubanzi obungamamitha angu-21.9 kanye nenqwaba yeshidi lensimbi ubude obungamamitha angu-36. Kunamasayizi ahlukahlukene namafomu ahlanganayo. Ngemuva kokuthi ukhonkolo ongaphansi kwamanzi ufinyelele izidingo zamandla, isivalo senqwaba kanye nomzimba womgodi kuzokwakhiwa ngokumpompa amanzi, futhi ukujula komklamo wokupompa amanzi kuzofinyelela kumamitha angama-20.

Ekwakhiweni kwe-hydraulic, indawo yokwakha ngokuvamile inkulu, futhi ivame ukusetshenziselwa ukwenza i-cofferdam yesakhiwo. Yakhiwe ngemizimba eminingi exhumene eyodwa, ngayinye eyakhiwe izinqwaba zamashidi ensimbi, futhi maphakathi nomzimba owodwa kugcwele inhlabathi. Ububanzi be-cofferdam bukhulu kakhulu, futhi udonga lwe-cofferdam alukwazi ukusekelwa ukwesekwa. Ngakho-ke, umzimba ngamunye ungamelana ngokuzimela ukugumbuqela, ukushelela futhi uvimbele ukuqhekeka kwengcindezi ekuxhumekeni. Okuvame ukusetshenziswa yizimo eziyindilinga nezihlukanisayo.

1.Inqwaba yeshidi lensimbi

2.Isakhiwo esihlangene nhlangothi zombili

3.Yakha izindonga emhlabathini namanzi

Amapharamitha wezinto ezibonakalayo

Ipuleti lensimbi elakheke ngokubanda

Inqwaba yeshidi lensimbi iqhubeka ngokubanda-yakha umucu wensimbi ukwenza ipuleti lesisekelo sokwakha elinesigaba somumo ongu-Z, umumo ongu-U noma ezinye izimo ezingaxhunywa komunye nomunye ngokhiye.

Inqwaba yeshidi lensimbi ekhiqizwa indlela yokugoqa okubandayo ingenye yemikhiqizo eyinhloko yensimbi egobayo ebandayo esetshenziswa kubunjiniyela bomphakathi. Inqwaba yeshidi lensimbi iqhutshwa (icindezelwe) esisekelweni ngomshayeli wenqwaba ukuze ayixhume ukuze enze udonga lwenqwaba yensimbi yokugcina inhlabathi namanzi. Izinhlobo zezigaba ezijwayelekile zifaka ipuleti elimise okwe-U, elimise u-Z kanye ne-straight-web. Inqwaba yeshidi lensimbi ilungele isisekelo esithambile kanye nokusekelwa komgodi ojulile onezinga eliphezulu lamanzi angaphansi komhlaba. Kulula ukwakha. Izinzuzo zayo ukusebenza kahle kokumisa amanzi futhi ingasetshenziswa kabusha. Isimo sokulethwa kwenqwaba yeshidi lensimbi Ubude bokulethwa kwenqwaba yeshidi lensimbi elakheke ngokubandayo buyi-6m, 9m, 12m, 15m, futhi ingacutshungulwa ngokuvumelana nezidingo zomsebenzisi. Ubude obukhulu bungama-24m. (Uma umsebenzisi enezidingo ezikhethekile zobude, zingabekwa phambili lapho zi-oda) Izinqwaba zeshidi lensimbi ezakhiwe ngendlela ebandayo zingalethwa ngokuya ngesisindo sangempela noma isisindo sethiyori. Ukusetshenziswa kwenqwaba yamashidi ensimbi Umkhiqizo wenqwaba yamashidi ensimbi owakhiwe ngendlela ebandayo unezici zokwakha okulula, inqubekela phambili esheshayo, asikho isidingo sempahla enkulu yokwakha, futhi ihambisana nomklamo wokuzamazama komhlaba ezinhlelweni zobunjiniyela bomphakathi. Ingaphinde iguqule umumo wesigaba nobude benqwaba yeshidi lensimbi elakhiwe ngendlela ebandayo ngokwesimo esithile sephrojekthi, ukuze wenze ukwakheka kwesakhiwo kube ngokwezomnotho futhi kunengqondo. Ukwengeza, ngomklamo wokwenza kahle wesigaba somkhiqizo wenqwaba yensimbi eyakhiwe ngendlela ebandayo, i-coefficient yekhwalithi yomkhiqizo ithuthukiswe kakhulu, isisindo ngemitha ngayinye yobubanzi bodonga lwenqwaba sehlisiwe, futhi izindleko zobunjiniyela zehlisiwe. [1]

Ipharamitha yobuchwepheshe

Ngokwenqubo yokukhiqiza, imikhiqizo yenqwaba yeshidi lensimbi ihlukaniswe yaba izinhlobo ezimbili: inqwaba yeshidi lensimbi elibandayo elakhiwe ngodonga olubandayo kanye nenqwaba yeshidi lensimbi eligoqwe elishisayo. Ekwakhiweni kobunjiniyela, uhla lwezicelo lwezinqwaba zamashidi ensimbi ezibandayo zincane, futhi eziningi zazo zisetshenziswa njengesengezo ezintweni ezisetshenzisiwe. Izinqwaba zamashidi ensimbi agingqiwe ashisayo bezilokhu ziyimikhiqizo ehamba phambili ezinhlelweni zobunjiniyela. Ngokusekelwe ezinzuzweni eziningi zezinqwaba zamashidi ensimbi ekwakhiweni, i-State Administration of Quality Supervision, Inspection and Quarantine kanye ne-National Standardization Administration yakhipha indinganiso kazwelonke "Hot rolled U-shaped steel sheet piles" ngoMeyi 14, 2007, eyaqalwa ngokusemthethweni ngoDisemba 1, 2007. Ekupheleni kwekhulu lama-20, i-Ultd yakhiqiza i-50. inqwaba yamashidi ensimbi anobubanzi obungu-400 mm ngenxa yezimo zemishini yobuchwepheshe yolayini wokukhiqiza umshini wokugaya ophuma phesheya, futhi wawasebenzisa ngempumelelo ku-cofferdam ye-Nenjiang Bridge, idokhi lamathani angu-300000 we-Jingjiang New Century Shipyard kanye nephrojekthi yokulawula izikhukhula e-Bangladesh. Kodwa-ke, ngenxa yokusebenza kahle kokukhiqiza, izinzuzo ezingezinhle zezomnotho, isidingo esiphansi sasekhaya kanye nolwazi lwezobuchwepheshe olunganele ngesikhathi sokukhiqiza isilingo, ukukhiqizwa akukwazanga ukuqhubeka. Ngokwezibalo, okwamanje, ukusetshenziswa kwaminyaka yonke kwezinqwaba zamashidi ensimbi eShayina kusasele cishe amathani ayi-30000, okubalelwa ku-1% kuphela wengqikithi yomhlaba wonke, futhi kunqunyelwe kumaphrojekthi athile ahlala njalo afana nokwakhiwa kwechweba, indawo yokubeka izikebhe kanye nokwakhiwa kwendawo yemikhumbi kanye namaphrojekthi wesikhashana afana ne-cofferdam yebhuloho nokusekelwa komgodi wesisekelo.

Inqwaba yeshidi lensimbi elakhiwe ngendlela ebandayo liyisakhiwo sensimbi esakhiwe ngokugoqeka okuqhubekayo kweyunithi eyakhiwe ngendlela ebandayo, futhi ukukhiya okusemaceleni kungagqitshwa ngokuqhubekayo ukuze kwakhiwe udonga lwenqwaba yamashidi. Inqwaba yeshidi lensimbi elakheke ngokubanda lenziwe ngamapuleti amancane (ngokuvamile angama-8 mm ~ 14 mm ubukhulu) futhi acutshungulwe yiyunithi yokwakha epholile. Izindleko zayo zokukhiqiza ziphansi futhi intengo ishibhile, nokulawula ukulinganisa kuyavumelana nezimo. Kodwa-ke, ngenxa yendlela yokucubungula elula, ubukhulu bengxenye ngayinye yenqwaba yomzimba buyafana, futhi ubukhulu besigaba abukwazi ukulungiswa, okuholela ekwandeni kokusetshenziswa kwensimbi; Ukuma kwengxenye yokukhiya kunzima ukulawula, futhi uxhumano alubopheli ngokuqinile futhi alukwazi ukumisa amanzi; Inqunyelwe umthamo wemishini yokucubungula egobayo ebandayo, kungakhiqizwa kuphela imikhiqizo enamandla aphansi kanye nogqinsi oluncane; Ngaphezu kwalokho, ukucindezeleka okukhiqizwa ohlelweni lokugoba okubandayo kukhulu kakhulu, futhi umzimba wenqwaba kulula ukuwudabula uma usetshenziswa, onomkhawulo omkhulu ekusetshenzisweni. Ekwakhiweni kobunjiniyela, uhla lwezicelo lwezinqwaba zamashidi ensimbi ezibandayo zincane, futhi eziningi zazo zisetshenziswa kuphela njengesengezo ezintweni ezisetshenzisiwe. Izici zenqwaba yeshidi lensimbi elakhiwe ngokubanda: ngokwesimo sangempela sephrojekthi, ingxenye yokonga kakhulu futhi enengqondo ingakhethwa ukuze kuzuzwe ukwenziwa kahle komklamo wephrojekthi, ukonga u-10-15% wezinto ezibonakalayo uma kuqhathaniswa nenqwaba yeshidi lensimbi egoqwe ngokushisa ngokusebenza okufanayo, ukunciphisa kakhulu izindleko zokwakha.

Thayipha isingeniso

Ukwethulwa okuyisisekelo kwenqwaba yeshidi lensimbi emise okwe-U

1.Umklamo wesakhiwo sesigaba se-WR uchungechunge lwezinqwaba zeshidi lensimbi unengqondo, futhi ubuchwepheshe bokwakha buthuthukisiwe, okwenza isilinganiso se-modulus yesigaba nesisindo semikhiqizo yenqwaba yensimbi iqhubeke ikhula, ukuze ikwazi ukuthola izinzuzo ezinhle zezomnotho ekusetshenzisweni nasekukhuliseni insimu yesicelo yezinqwaba zeshidi lensimbi elakhiwe ngokubandayo.

2.Inqwaba yeshidi lensimbi ye-WRU inezincazelo ezihlukahlukene namamodeli.

3.Idizayinelwe futhi yakhiqizwa ngokwezinga laseYurophu, isakhiwo esivumelanayo sivumela ukusetshenziswa okuphindaphindiwe, okulingana nokugoqa okushisayo mayelana nokusetshenziswa okuphindaphindiwe, futhi kune-angle amplitude ethile, elungele ukulungisa ukuchezuka kokwakhiwa.

4.Ukusetshenziswa kwensimbi enamandla kakhulu kanye nemishini yokukhiqiza ethuthukisiwe kuqinisekisa ukusebenza kwezinqwaba zamashidi ensimbi abandayo.

5.Ubude bungenziwa ngokwezifiso ngokwezidingo zekhasimende, okuletha lula ekwakhiweni futhi kunciphisa izindleko.

6.Ngenxa yokunethezeka kokukhiqiza, inga-odwa ngaphambili ngaphambi kokulethwa lapho isetshenziswa nezinqwaba eziyinhlanganisela.

7.Umjikelezo wokukhiqiza nokukhiqiza kufushane, futhi ukusebenza kwezinqwaba zeshidi lensimbi kunganqunywa ngokuvumelana nezidingo zamakhasimende.

Inganekwane kanye nezinzuzo zenqwaba yeshidi lensimbi elimise okwe-U

1.Izinqwaba zeshidi lensimbi ezimise okwe-U zinezincazelo namamodeli ahlukahlukene.

2.Idizayinwe futhi ikhiqizwe ngokuvumelana nezindinganiso zase-Europe, nefomu lesakhiwo esivumelanayo, elivumela ukusetshenziswa kabusha, futhi kulingana nokugoqeka okushisayo mayelana nokusetshenziswa kabusha.

3.Ubude bungenziwa ngokwezifiso ngokwezidingo zekhasimende, okuletha lula ekwakhiweni futhi kunciphisa izindleko.

4.Ngenxa yokunethezeka kokukhiqiza, inga-odwa ngaphambili ngaphambi kokulethwa lapho isetshenziswa nezinqwaba eziyinhlanganisela.

5.Umjikelezo wokukhiqiza nokukhiqiza kufushane, futhi ukusebenza kwezinqwaba zeshidi lensimbi kunganqunywa ngokuvumelana nezidingo zamakhasimende.

Imininingwane ejwayelekile yenqwaba yeshidi lensimbi emise okwe-u

| Uhlobo | Ububanzi | Ubude | Ubukhulu | Indawo yesigaba | Isisindo ngenqwaba | Isisindo ngodonga ngalunye | Isikhathi se-Inertia | I-modulus yesigaba |

| mm | mm | mm | Cm2/m | Kg/m | Kg/m2 | Cm4/m | Cm3/m | |

| I-WRU7 | 750 | 320 | 5 | 71.3 | 42.0 | 56.0 | 10725 | 670 |

| I-WRU8 | 750 | 320 | 6 | 86.7 | 51.0 | 68.1 | 13169 | 823 |

| I-WRU9 | 750 | 320 | 7 | 101.4 | 59.7 | 79.6 | 15251 | 953 |

| I-WRU10-450 | 450 | 360 | 8 | 148.6 | 52.5 | 116.7 | 18268 | 1015 |

| I-WRU11-450 | 450 | 360 | 9 | 165.9 | 58.6 | 130.2 | 20375 | 1132 |

| I-WRU12-450 | 450 | 360 | 10 | 182.9 | 64.7 | 143.8 | 22444 | 1247 |

| I-WRU11-575 | 575 | 360 | 8 | 133.8 | 60.4 | 105.1 | 19685 | 1094 |

| I-WRU12-575 | 575 | 360 | 9 | 149.5 | 67.5 | 117.4 | 21973 | 1221 |

| I-WRU13-575 | 575 | 360 | 10 | 165.0 | 74.5 | 129.5 | 24224 | 1346 |

| I-WRU11-600 | 600 | 360 | 8 | 131.4 | 61.9 | 103.2 | 19897 | 1105 |

| I-WRU12-600 | 600 | 360 | 9 | 147.3 | 69.5 | 115.8 | 22213 | 1234 |

| I-WRU13-600 | 600 | 360 | 10 | 162.4 | 76.5 | 127.5 | 24491 | 1361 |

| I-WRU18-600 | 600 | 350 | 12 | 220.3 | 103.8 | 172.9 | 32797 | 1874 |

| I-WRU20-600 | 600 | 350 | 13 | 238.5 | 112.3 | 187.2 | 35224 | 2013 |

| I-WRU16 | 650 | 480 | 8. | 138.5 | 71.3 | 109.6 | 39864 | 1661 |

| I-WRU 18 | 650 | 480 | 9 | 156.1 | 79.5 | 122.3 | 44521 | 1855 |

| I-WRU20 | 650 | 540 | 8 | 153.7 | 78.1 | 120.2 | 56002 | 2074 |

| I-WRU23 | 650 | 540 | 9 | 169.4 | 87.3 | 133.0 | 61084 | 2318 |

| I-WRU26 | 650 | 540 | 10 | 187.4 | 96.2 | 146.9 | 69093 | 2559 |

| I-WRU30-700 | 700 | 558 | 11 | 217.1 | 119.3 | 170.5 | 83139 | 2980 |

| I-WRU32-700 | 700 | 560 | 12 | 236.2 | 129.8 | 185.4 | 90880 | 3246 |

| I-WRU35-700 | 700 | 562 | 13 | 255.1 | 140.2 | 200.3 | 98652 | 3511 |

| I-WRU36-700 | 700 | 558 | 14 | 284.3 | 156.2 | 223.2 | 102145 | 3661 |

| I-WRU39-700 | 700 | 560 | 15 | 303.8 | 166.9 | 238.5 | 109655 | 3916 |

| I-WRU41-700 | 700 | 562 | 16 | 323.1 | 177.6 | 253.7 | 117194 | 4170 |

| I-WRU 32 | 750 | 598 | 11 | 215.9 | 127.1 | 169.5 | 97362 | 3265 |

| I-WRU 35 | 750 | 600 | 12 | 234.9 | 138.3 | 184.4 | 106416 | 3547 |

| I-WRU36-700 | 700 | 558 | 14 | 284.3 | 156.2 | 223.2 | 102145 | 3661 |

| I-WRU39-700 | 700 | 560 | 15 | 303.8 | 166.9 | 238.5 | 109655 | 3916 |

| I-WRU41-700 | 700 | 562 | 16 | 323.1 | 177.6 | 253.7 | 117194 | 4170 |

| I-WRU 32 | 750 | 598 | 11 | 215.9 | 127.1 | 169.5 | 97362 | 3265 |

| I-WRU 35 | 750 | 600 | 12 | 234.9 | 138.3 | 184.4 | 106416 | 3547 |

| Isiqephu 38 | 750 | 602 | 13 | 253.7 | 149.4 | 199.2 | 115505 | 3837 |

| I-WRU 40 | 750 | 598 | 14 | 282.2 | 166.1 | 221.5 | 119918 | 4011 |

| I-WRU 43 | 750 | 600 | 15 | 301.5 | 177.5 | 236.7 | 128724 | 4291 |

| I-WRU 45 | 750 | 602 | 16 | 320.8 | 188.9 | 251.8 | 137561 | 4570 |

Inqwaba yeshidi lensimbi emise okwe-Z

Ukuvuleka kokukhiya kusatshalaliswa ngokulinganayo ezinhlangothini zombili ze-axis engathathi hlangothi, futhi iwebhu iyaqhubeka, okuthuthukisa kakhulu i-modulus yesigaba nokuqina kokugoba, futhi iqinisekisa ukuthi izakhiwo zemishini zesigaba zingathuthukiswa ngokugcwele. Ngenxa yokwakheka kwesigaba esiyingqayizivele kanye nokukhiya okuthembekile kwe-Larssen.

Izinzuzo nezithonjana zenqwaba yeshidi lensimbi elimise okuka-Z

1.Idizayini eguquguqukayo enemodulus yesigaba esiphezulu kanye nesilinganiso sobuningi.

2.Umzuzu we-inertia ophakeme ukhulisa ukuqina kodonga lwenqwaba yeshidi futhi unciphise ukugudluka nokuguqulwa.

3.Ububanzi obukhulu, okusindisa ngokuphumelelayo isikhathi sokuphakamisa nokunqwabelanisa.

4.Ngokukhula kobubanzi besigaba, inani lokuncipha kodonga lwenqwaba yeshidi liyancishiswa, futhi ukusebenza kwawo kokuvalwa kwamanzi kuthuthukiswa ngokuqondile.

5.Izingxenye ezigqwalile kakhulu ziye zajiya, futhi ukumelana nokugqwala kuhle kakhulu.

Ukucaciswa okujwayelekile kwenqwaba yeshidi lensimbi emise okwe-Z

| Uhlobo | Ububanzi | Ubude | Ubukhulu | Indawo yesigaba | Isisindo ngenqwaba | Isisindo ngodonga ngalunye | Isikhathi se-Inertia | I-modulus yesigaba |

| mm | mm | mm | Cm2/m | Kg/m | Kg/m2 | Cm4/m | Cm3/m | |

| I-WRZ16-635 | 635 | 379 | 7 | 123.4 | 61.5 | 96.9 | 30502 | 1610 |

| I-WRZ18-635 | 635 | 380 | 8 | 140.6 | 70.1 | 110.3 | 34717 | 1827 |

| I-WRZ28-635 | 635 | 419 | 11 | 209.0 | 104.2 | 164.1 | 28785 | 2805 |

| I-WRZ30-635 | 635 | 420 | 12 | 227.3 | 113.3 | 178.4 | 63889 | 3042 |

| I-WRZ32-635 | 635 | 421 | 13 | 245.4 | 122.3 | 192.7 | 68954 | 3276 |

| I-WRZ12-650 | 650 | 319 | 7 | 113.2 | 57.8 | 88.9 | 19603 | 1229 |

| I-WRZ14-650 | 650 | 320 | 8 | 128.9 | 65.8 | 101.2 | 22312 | 1395 |

| I-WRZ34-675 | 675 | 490 | 12 | 224.4 | 118.9 | 176.1 | 84657 | 3455 |

| I-WRZ37-675 | 675 | 491 | 13 | 242.3 | 128.4 | 190.2 | 91327 | 3720 |

| I-WRZ38-675 | 675 | 491.5 | 13.5 | 251.3 | 133.1 | 197.2 | 94699 | 3853 |

| I-WRZ18-685 | 685 | 401 | 9 | 144 | 77.4 | 113 | 37335 | 1862 |

| I-WRZ20-685 | 685 | 402 | 10 | 159.4 | 85.7 | 125.2 | 41304 | 2055 |

Inqwaba yeshidi lensimbi ye-L/S

Uhlobo lwe-L lusetshenziswa kakhulu ukuxhasa uthango, udonga lwedamu, ukumba iziteshi kanye nokufaka imisele.

Isigaba silula, isikhala esithathwe odongeni lwenqwaba sincane, ukukhiya kusendaweni efanayo, futhi ukwakhiwa kulula. Isebenza ekumbiweni kokwakhiwa kobunjiniyela bakamasipala.

| Imininingwane ejwayelekile yenqwaba yeshidi lensimbi emise okwe-L | |||||||

| Uhlobo | Ububanzi | Ubude | Ubukhulu | Isisindo ngenqwaba | Isisindo ngodonga ngalunye | Isikhathi se-Inertia | I-modulus yesigaba |

| mm | mm | mm | Kg/m | Kg/m2 | Cm4/m | Cm3/m | |

| I-WRL1.5 | 700 | 100 | 3.0 | 21.4 | 30.6 | 724 | 145 |

| I-WRL2 | 700 | 150 | 3.0 | 22.9 | 32.7 | 1674 | 223 |

| I-WRI3 | 700 | 150 | 4.5 | 35.0 | 50.0 | 2469 | 329 |

| I-WRL4 | 700 | 180 | 5.0 | 40.4 | 57.7 | 3979 | 442 |

| I-WRL5 | 700 | 180 | 6.5 | 52.7 | 75.3 | 5094 | 566 |

| I-WRL6 | 700 | 180 | 7.0 | 57.1 | 81.6 | 5458 | 606 |

| Ukucaciswa okujwayelekile kwenqwaba yeshidi lensimbi emise okwe-s | |||||||

| Uhlobo | Ububanzi | Ubude | Ubukhulu | Isisindo ngenqwaba | Isisindo ngodonga ngalunye | Isikhathi se-Inertia | I-modulus yesigaba |

| mm | mm | mm | Kg/m | Kg/m2 | Cm4/m | Cm3/m | |

| I-WRS4 | 600 | 260 | 3.5 | 31.2 | 41.7 | 5528 | 425 |

| I-WRS5 | 600 | 260 | 4.0 | 36.6 | 48.8 | 6703 | 516 |

| I-WRS6 | 700 | 260 | 5.0 | 45.3 | 57.7 | 7899 | 608 |

| I-WRS8 | 700 | 320 | 5.5 | 53.0 | 70.7 | 12987 | 812 |

| I-WRS9 | 700 | 320 | 6.5 | 62.6 | 83.4 | 15225 | 952 |

Olunye uhlobo lwenqwaba yeshidi lensimbi yohlobo oluqondile lufanelekile ukumba kweminye imisele, ikakhulukazi lapho isikhala phakathi kwezakhiwo ezimbili sincane futhi ukumba kuyadingeka, ngoba ukuphakama kwayo kuphansi futhi kuseduze nomugqa oqondile.

Izinzuzo nezithonjana zezinqwaba zamashidi ensimbi

Okokuqala, ingakha udonga lwenqwaba yeshidi lensimbi oluzinzile ukuze kuqinisekiswe ukumbiwa okushelelayo okuya phansi ngaphandle kokuthintwa ukunyathela ezinhlangothini zombili namanzi angaphansi komhlaba.

Okwesibili, kuyasiza futhi ukuzinzisa isisekelo, ngaleyo ndlela kuqinisekiswe ukuzinza kwezakhiwo ezinhlangothini zombili.

| Ukucaciswa okujwayelekile kwenqwaba yeshidi lensimbi | |||||||||||||||||

| Uhlobo | Ububanzi mm | Ubude mm | Ubukhulu mm | Indawo yesigaba cm2/m | Isisindo | Isikhathi se-Inertia cm4/m | I-modulus yesigaba cm3/ m | ||||||||||

| Isisindo ngephilisi ngalinye kg/m | Isisindo nge-wallkg/m2 | ||||||||||||||||

| I-WRX 600-10 | 600 | 60 | 10.0 | 144.8 | 68.2 | 113.6 | 396 | 132 | |||||||||

| I-WRX600-11 | 600 | 61 | 11.0 | 158.5 | 74.7 | 124.4 | 435 | 143 | |||||||||

| I-WRX600-12 | 600 | 62 | 12.0 | 172.1 | 81.1 | 135.1 | 474 | 153 | |||||||||

| Izinga lokubunjwa kwamakhemikhali kanye nezakhiwo zemishini yezinto eziqukethwe ezibandayo ezakhiwe ngenqwaba yensimbi I-GB/T700-1988 GB/T1591-1994 GB/T4171-2000 | |||||||||||||||||

| Ibhrendi | Ukwakheka kwamakhemikhali | Impahla yemishini | |||||||||||||||

| C | Si | Mn | P | S | veza amandlaMpa | qinisa uMpa | Ukwelula | Amandla okuthinta | |||||||||

| Q345B | s0.20 | ≤0.50 | ≤1.5 | ≤0.025 | ≤0.020 | 2345 | 470-630 | ≥21 | 234 | ||||||||

| Q235B | 0.12-0.2 | s0.30 | 0.3-0.7 | ≤0.045 | ≤0.045 | ≥235 | 375-500 | 226 | 227 | ||||||||

Ipuleti lensimbi eligoqelwe ngokushisayo

Izinqwaba zeshidi lensimbi eligoqiwe elishisayo, njengoba negama lisho, yizinqwaba zamashidi ensimbi akhiqizwa ngokushisela nokugoqeka okushisayo. Ngenxa yobuchwepheshe obuphambili, ukulunywa kwayo kokukhiya kunokumelana namanzi okuqinile.

Isibonelo sepharamitha

| Izici zesigaba senqwaba yeshidi lensimbi egoqwe ashisayo | ||||||||||||||||

| Uhlobo | Usayizi wesigaba | Isisindo ngenqwaba | Isisindo ngodonga ngalunye | |||||||||||||

| Ububanzi | Ubude | Ubukhulu | Ingxenye indawo | Isisindo sethiyori | Umzuzu we Inertia | I-modulus ye ingxenye | Indawo yesigaba | Ithiyori isisindo | Umzuzu we Inertia | I-modulus ye ingxenye | ||||||

| mm | mm | mm | cmz | cm2 | Kg/m | Cm3/m | cm7/m | cm2/m | Kg/m? | cm4 | cm3/m | |||||

| I-SKSP- Ⅱ | 400 | 100 | 10.5 | 61.18 | 48.0 | 1240 | 152 | 153.0 | 120 | 8740 | 874 | |||||

| I-SKSP-Ⅲ | 400 | 125 | 13.0 | 76.42 | 60.0 | 2220 | 223 | 191.0 | 150 | 16800 | 1340 | |||||

| I-SKSP-IV | 400 | 170 | 15.5 | 96.99 | 76.1 | 4670 | 362 | 242.5 | 190 | 38600 | 2270 | |||||

| Ithebula lezinga lensimbi, ukwakheka kwamakhemikhali kanye nemingcele yempahla yemishini yenqwaba yeshidi lensimbi egoqwe ngokushisayo | ||||||||||||||||

| Inombolo yokubiza | Uhlobo | Ukwakheka kwamakhemikhali | Ukuhlaziywa komshini | |||||||||||||

| C | Si | UMn | P | S | N | Amandla okukhiqiza N/mm | Amandla okubamba N/mm | Ukwelula | ||||||||

| I-JIS A5523 | SYW295 | 0.18 ubuningi | 0.55 ubuningi | 1.5 ubuningi | 0.04 ubuningi | 0.04 ubuningi | 0.006 ubuningi | > 295 | > 490 | >17 | ||||||

| SYW390 | 0.18 ubuningi | 0.55 ubuningi | 1.5 ubuningi | 0.04 ubuningi | 0.04 3X | 0.006 ubuningi | 0.44 ubuningi | > 540 | >15 | |||||||

| I-JIS A5528 | I-SY295 | 0.04 ubuningi | 0.04 ubuningi | > 295 | > 490 | >17 | ||||||||||

| I-SY390 | 0.04 ubuningi | 0.04 ubuningi | > 540 | >15 | ||||||||||||

Isigaba somumo

Inqwaba yeshidi lensimbi emise okwe-U

Izinqwaba zeshidi lensimbi elihlanganisiwe

Izici

Izici zohlelo lokusebenza:

1.Phatha futhi uxazulule uchungechunge lwezinkinga ohlelweni lwezimayini.

2.Ukwakhiwa okulula kanye nesikhathi sokwakha esifushane.

3.Ngomsebenzi wokwakha, kunganciphisa izidingo zesikhala.

4.Ukusetshenziswa kwezinqwaba zamashidi ensimbi kunganikeza ukuphepha okudingekayo futhi kube nesikhathi esiqinile (sokusiza inhlekelele).

5.Ukusetshenziswa kwezinqwaba zeshidi lensimbi akukwazi ukuvinjelwa izimo zezulu; Enqubweni yokusebenzisa izinqwaba zeshidi lensimbi, kungenza kube lula izinqubo eziyinkimbinkimbi zokuhlola ukusebenza kwezinto noma izinhlelo ukuze kuqinisekiswe ukuguquguquka kwazo, ukushintshashintsha okuhle, futhi kungasetshenziswa kabusha.

6.Ingagaywa kabusha futhi isetshenziswe kabusha ukuze wonge imali.

Ubunjiniyela be-Hydraulic - izakhiwo eziseduze nemizila yokuthutha echwebeni - imigwaqo nojantshi

1.Udonga lwe-Wharf, udonga lokulungisa kanye nodonga olubambayo;.

2.Ukwakhiwa kwamadokodo nezindawo zemikhumbi kanye nezindonga zokuhlukanisa umsindo.

3.Inqwaba yokuvikela izinti, (i-wharf) i-bollard, isisekelo sebhuloho.

4.I-radar rangefinder, umthambeka, umthambeka.

5.Umzila wesitimela ocwilayo kanye nokugcinwa kwamanzi angaphansi komhlaba.

6.Umhubhe.

Imisebenzi ye-Civil of Waterway:

1.Ukugcinwa kwemigwaqo yamanzi.

2.Udonga olubambayo.

3.Hlanganisa i-subgrade kanye ne-embankment.

4.Imishini ye-berthing; Vimbela ukukhuhla.

Ukulawulwa kokungcola kwezakhiwo zobunjiniyela zokonga amanzi - izindawo ezingcolile, ukugcwaliswa kocingo:

1.Izingidi zemikhumbi, izingidi zamanzi, nezinsimbi ezivaliwe (zemifula).

2.I-Weir, i-embankment, ukumba ukuze kushintshwe inhlabathi.

3.Isisekelo sebhuloho nendawo evalekile yethangi lamanzi.

4.I-Culvert (umgwaqo onguthelawayeka, ujantshi, njll.);, Ukuvikelwa kwesiteshi sekhebula esingaphansi komhlaba emthambekeni ophezulu.

5.Umnyango wokuphepha.

6.Ukuncishiswa komsindo wonqenqema lokulawula izikhukhula.

7.Ikholomu yebhuloho kanye nodonga lokuhlukaniswa komsindo we-wharf;

8.Ukwakheka kwamakhemikhali kanye nezakhiwo zemishini zezinto ezibandayo ezakhiwe ngenqwaba yensimbi. [1]

Izinzuzo:

1.Ngomthamo oqinile wokuthwala kanye nesakhiwo sokukhanya, udonga oluqhubekayo olwakhiwe izinqwaba zeshidi lensimbi lunamandla aphezulu kanye nokuqina.

2.Ukuqina kwamanzi kuhle, futhi ukukhiya ekuxhumekeni kwenqwaba yeshidi lensimbi kuhlanganiswe ngokuqinile, okungavimbela ngokwemvelo ukuphuma kwamanzi.

3.Ukwakhiwa kulula, kungakwazi ukuzivumelanisa nezimo ezihlukahlukene ze-geological kanye nekhwalithi yenhlabathi, kunganciphisa umthamo wokumba womgodi wesisekelo, futhi ukusebenza kuthatha indawo encane.

4.Ukuqina okuhle. Ngokuya ngomehluko endaweni yokusetshenziswa, impilo yesevisi ingaba yiminyaka engama-50.

5.Ukwakhiwa kuhambisana nemvelo, futhi inani lenhlabathi nokhonkolo othathwe liyancipha kakhulu, elingavikela ngokuphumelelayo imithombo yomhlaba.

6.Umsebenzi usebenza kahle, futhi ufanele kakhulu ukuqaliswa ngokushesha kokulawulwa kwezikhukhula, ukuwa, isihlabathi esisheshayo, ukuzamazama komhlaba nokunye ukusiza nokuvimbela izinhlekelele.

7.Izinto zokwakha zingaphinda zisetshenziswe futhi ziphinde zisetshenziswe izikhathi ezingu-20-30 emisebenzini yesikhashana.

8.Uma kuqhathaniswa nezinye izakhiwo ezilodwa, udonga lulula futhi lukwazi ukuguquguquka okukhulu, okulungele ukuvimbela nokwelashwa kwezinhlekelele ezihlukahlukene ze-geological.

Isicelo

Umsebenzi, ukubukeka kanye nenani elingokoqobo yizindinganiso ezisetshenziswa abantu lapho bekhetha izinto zokwakha namuhla. Izinqwaba zamashidi ensimbi zihambisana namaphuzu amathathu angenhla: izakhi zezingxenye zayo zokukhiqiza zinikeza isakhiwo esilula nesisebenzayo, zihlangabezana nazo zonke izidingo zokuphepha kwesakhiwo nokuvikelwa kwemvelo, futhi izakhiwo eziqedwe yizinqwaba zamashidi ensimbi zinokukhanga okukhulu.

Ukusetshenziswa kwezinqwaba zamashidi ensimbi kudlulela futhi kudlulele kuyo yonke imboni yezokwakha, kusukela ekusetshenzisweni kobunjiniyela bendabuko bokongiwa kwamanzi kanye nobuchwepheshe bomphakathi, kanye nokusetshenziswa kukaloliwe kanye nethilamu kuya ekusetshenzisweni kokulawula ukungcoliswa kwemvelo.

Ukubaluleka okungokoqobo kwezinqwaba zamashidi ensimbi kuye kwabonakala ekukhiqizeni okusha kwemikhiqizo eminingi emisha, njengalezi: ezinye izakhiwo ezikhethekile ezishiselwe; Ipuleti lensimbi elenziwe umshayeli wenqwaba ye-hydraulic vibratory; I-sluice evaliwe nokwelashwa kopende wasembonini. Izici eziningi ziqinisekisa ukuthi izinqwaba zeshidi lensimbi zigcina enye yezinto eziwusizo kakhulu zengxenye yokukhiqiza, okungukuthi, akusizi nje kuphela ubuhle bekhwalithi yensimbi, kodwa futhi kulungele ucwaningo nokuthuthukiswa kwemakethe yenqwaba yamashidi ensimbi; Kuyasiza ekwakhiweni kokuthuthukiswa kwezici zomkhiqizo ukuze kuhlangatshezwane kangcono nezidingo zabasebenzisi.

Ukuthuthukiswa kokufakwa uphawu okukhethekile nobuchwepheshe bokuphrinta ngokweqile kuyisibonelo esihle salokhu. Isibonelo, uhlelo lwelungelo lobunikazi lwe-HOESCH luvule insimu entsha ebalulekile yenqwaba yeshidi lensimbi ekulawuleni ukungcola.

Njengoba inqwaba yeshidi lensimbi ye-HOESCH yasetshenziswa njengodonga lokugcina oluvalwe mpo ngo-1986 ukuze kuvikelwe umhlaba ongcolile, kutholakale ukuthi inqwaba yeshidi lensimbi ihlangabezana nazo zonke izidingo zokuvimbela ukuvuza kwamanzi nokungcola. Izinzuzo zezinqwaba zeshidi lensimbi njengezindonga ezigcinayo zisetshenziswa kancane kancane kwezinye izinkambu.

Okulandelayo ngezinye zezindawo ezisebenza kahle kakhulu zobunjiniyela be-geotechnical kanye nezicelo zokufakwa kwezinqwaba zamashidi ensimbi:

* I-Cofferdam

* Ukuphambukisa nokulawula izikhukhula zomfula

* Uthango lohlelo lokwelapha amanzi

* Ukulawulwa kwezikhukhula

* Indawo ebiyelwe

* I-dike yokuzivikela

* Ukubuyiswa kogu

* Ukusikwa komhubhe nendawo yokukhosela yomhubhe

* I-breakwater

* I-Weir wall

* Ukulungiswa komthambeka

* Baffle wall

Izinzuzo zokusebenzisa ucingo lwenqwaba yensimbi:

* Akukho kumbiwa okudingekayo ukuze kuncishiswe ukulahlwa kwemfucuza

* Uma kunesidingo, inqwaba yeshidi lensimbi ingasuswa ngemuva kokusetshenziswa

* Akuthintwa i-topography namanzi angaphansi ajulile

* Ukumba okungekho emthethweni kungasetshenziswa

* Ukwakhiwa kungenziwa emkhunjini ngaphandle kokuhlela enye indawo

Inqubo yokwakha

Lungiselela

1.Ukulungiswa kokwakhiwa: ngaphambi kokushayela inqwaba, inotshi ephuzwini lenqwaba izovalwa ukuze kugwenywe ukukhama kwenhlabathi, futhi umlomo wokukhiya uzogcotshwa ibhotela noma amanye amafutha. Ukuze uthole izinqwaba zeshidi lensimbi eziye zangalungiswa isikhathi eside, umlomo wokukhiya okhubazekile futhi zigqwalile kakhulu, kufanele zilungiswe futhi zilungiswe. Ezinqwaba ezigobile nezikhubazekile, zingalungiswa nge-hydraulic jack jacking noma ukomiswa komlilo.

2.Ukuhlukaniswa kwesigaba sokugeleza kokushayela inqwaba.

3.Ngesikhathi sokushayela inqwaba. Ukuqinisekisa ukuma kwezinqwaba zeshidi lensimbi. Sebenzisa ama-theodolite amabili ukulawula ngezindlela ezimbili.

4.Indawo kanye nesiqondiso sezinqwaba zeshidi lensimbi lokuqala nelesibili okufanele zishayelwe kufanele kube nembayo, ukuze kudlale indima yesifanekiso esiqondisayo. Ngakho-ke, ukulinganisa kuzokwenziwa kanye njalo nge-1m yokushayela, futhi i-reinforcement noma ipuleti lensimbi lizoshiselwa ngokusekelwa kwe-purlin ukuze kulungiswe isikhashana ngokushesha ngemva kokushayela ekujuleni okunqunywe kusengaphambili.

Idizayini

1. Ukukhethwa kwendlela yokushayela

Inqubo yokwakha izinqwaba zeshidi lensimbi iyindlela yokushayela ehlukene, eqala ekhoneni elilodwa lodonga lweshidi futhi iqhutshwa eyodwa (noma ezimbili eqenjini) kuze kube sekupheleni kwephrojekthi. Izinzuzo zayo zilula futhi zilula ukwakhiwa futhi asikho isidingo sezinye izisekelo ezisizayo. Ububi bayo ukuthi kulula ukutshekisela inqwaba yeshidi ohlangothini olulodwa, futhi kunzima ukuyilungisa ngemva kokunqwabelana kwamaphutha. Ngakho-ke, indlela yokushayela ehlukile isebenza kuphela esimweni lapho izidingo zodonga lwenqwaba yeshidi zingekho phezulu futhi ubude benqwaba yeshidi buncane (njengamamitha angaphansi kwe-10).

2.Indlela yokushayela isikrini iwukufaka izinqwaba zamashidi ensimbi angu-10-20 kuhlaka lomhlahlandlela ngemigqa, bese uzishayela ngamaqoqo. Ngesikhathi sokushayela, izinqwaba zeshidi lensimbi kuzo zombili iziphetho zodonga lwesikrini zizoshayelwa endaweni ephakeme yokuklama noma ekujuleni okuthile ukuze zibe yinqwaba yeshidi lokumisa, bese lishayelwa phakathi nezinyathelo zobude benqwaba yeshidi elingu-1/3 no-1/2. Izinzuzo zendlela yokushayela isikrini yilezi: kunganciphisa ukuqoqwa kwephutha lokuthambekela, kuvimbele ukuthambekela ngokweqile, futhi kulula ukufeza ukuvala nokuqinisekisa ikhwalithi yokwakhiwa kodonga lwenqwaba yamashidi. Okubi ukuthi ukuphakama okuzimele kwenqwaba efakiwe kuphakeme kakhulu, futhi kufanele kuqashelwe ukuzinza nokuphepha kokwakhiwa kwenqwaba efakiwe.

3.Ukushayela izinqwaba zeshidi lensimbi.

Ngesikhathi sokushayela inqwaba, indawo yokushayela kanye nokuqondisa kwezinqwaba zamashidi ensimbi yokuqala neyesibili okufanele ziqhutshwe kufanele kuqinisekise ukunemba. Ingadlala indima yokuqondisa kwesifanekiso. Ngokuvamile, kufanele ikalwe kanye njalo nge-1m ngokushayelwa. Ukwakhiwa kwekhona kanye nokuvalwa okuvaliwe kwenqwaba yeshidi lensimbi kungathatha inqwaba yeshidi elimise okukhethekile, indlela yesixhumi, indlela egqagqene kanye nendlela yokulungisa i-axis. Ukuze kuqinisekiswe ukwakhiwa okuphephile, kuyadingeka ukubheka nokuvikela amapayipi abalulekile kanye nezintambo ezinamandla kagesi ngaphakathi kwendawo yokusebenza.

4.Ukususwa kwezinqwaba zeshidi lensimbi.

Lapho ugcwalisa umgodi wesisekelo, inqwaba yeshidi lensimbi izokhishwa ukuze isetshenziswe kabusha ngemva kokuqeda. Ngaphambi kokukhipha, ukulandelana kokukhipha, isikhathi sokukhipha kanye nendlela yokwelapha imigodi yenqwaba yezinqwaba zamashidi ensimbi kufanele kufundwe. Ukuze unqobe ukumelana kwezinqwaba zamashidi, ngokusho kwemishini yokudonsa inqwaba esetshenzisiwe, izindlela zokudonsa inqwaba zihlanganisa ukudonsa kwenqwaba okumile, ukudonsa kwenqwaba yokudlidliza kanye nokudonsa inqwaba nomthelela. Ngesikhathi sokusebenza kokukhipha, naka ukubuka nokuvikela amapayipi abalulekile kanye nezintambo ezinamandla kagesi ngaphakathi kwendawo yokusebenza. [1]

Izisetshenziswa

1.Imishini yokunqwabelanisa imithelela: isando sokuwa samahhala, isando somusi, isando somoya, isando esisebenza ngogesi, isando sikadizili, njll.

2.Imishini yokushayela inqwaba edlidlizayo: Lolu hlobo lwemishini lungasetshenziswa kukho kokubili ukushayela nokudonsa izinqwaba, futhi okuvame ukusetshenziswa yinqwaba yokushayela nokudonsa isando.

3.Umshini wokushayela wenqwaba yokudlidliza kanye nomthelela: lolu hlobo lomshini lufakwe indlela enomthelela phakathi komzimba womshayeli wenqwaba yokudlidliza kanye ne-clamp. Lapho i-exciter yokudlidliza ikhiqiza ukudlidliza okuya phezulu naphansi, ikhiqiza amandla okuthinta, athuthukisa kakhulu ukusebenza kahle kokwakha.

4.Umshini wokushayela inqwaba emile: cindezela inqwaba yeshidi emhlabathini ngamandla amile.