Ipuleti lensimbi engagqwali

Incazelo Yomkhiqizo

Ngokwendlela yokukhiqiza, kunezinhlobo ezimbili zokugoqa okushisayo nokubandayo, okuhlanganisa ishidi eliwugqinsi elingu-0.5-4 mm kanye nepuleti eliwugqinsi elingu-4.5-35 mm.

Ngokwezici zesakhiwo sensimbi, ingahlukaniswa ngezinhlobo ezinhlanu: i-austenite, i-austenitic-ferrite, i-ferrite, i-martensite kanye nokuqina kwezulu.

Indawo esetshenziswayo: ithwala ukugqwala kwe-oxalic acid, i-sulfate-ferric sulfate, i-nitric acid, i-nitric acid-hydrofluoric acid, i-sulfate-copper sulfate, i-phosphoric acid, i-formic acid, i-acetic acid namanye ama-acids.

Ukusetshenziswa: okusetshenziselwa amakhemikhali, ukudla, imithi, iphepha, uwoyela, amandla e-athomu nezinye izimboni, kanye nezingxenye ezihlukahlukene nezingxenye zezakhiwo, i-kitchenware, i-tableware, izimoto kanye nempahla yasendlini.Ukuze kuqinisekiswe ukuthi amandla okukhiqiza, amandla aqinile, ubude, ubulukhuni kanye nezinye izakhiwo zemishini yamapuleti ensimbi ahlukahlukene ahlangabezana nezidingo, amapuleti ensimbi kufanele afakwe i-annealing, ukwelashwa kwesixazululo, ukwelashwa kokuguga nokunye ukwelashwa kokushisa ngaphambi kokubeletha.

Izidingo zekhwalithi: ipuleti lensimbi engagqwali linendawo ebushelelezi, ipulasitiki ephezulu, ukuqina namandla emishini, futhi imelana nokugqwala kwe-asidi, igesi ye-alkali, isixazululo neminye imidiya.Kuyinsimbi okungelula ukugqwala, kodwa ayinalo nhlobo ukugqwala.Ukumelana nokugqwala kwensimbi engagqwali ikakhulukazi kuncike ekwakhekeni kwengxubevange yayo (i-chromium, i-nickel, i-titanium, i-silicon, i-aluminium, njll.) kanye nesakhiwo sangaphakathi.Indima eyinhloko i-chromium.I-Chromium inokusimama okuphezulu kwamakhemikhali, ingenza ifilimu ye-passivation endaweni yensimbi, ihlukanise insimbi ngaphandle, ivikele ipuleti lensimbi ekufakweni kwe-oxidation, futhi ikhulise ukumelana nokugqwala kwepuleti lensimbi.Ngemuva kokubhujiswa kwefilimu ye-passivation, ukumelana nokugqwala kuzokwehla.

Ukwakheka Kwamakhemikhali

| Ikhodi yokufundisa ehlanganisiwe | Ibhrendi | Ukwakheka kwamakhemikhali (ingxenyana yobuningi)/% | ||||||||||||||||||||||||||||||||||

| c | Si | Mn | P | S | Ni | Cr | Mo | N | Cu | Okunye | ||||||||||||||||||||||||||

| I-S30408 | 06Cr19Ni10 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 8.00~ 10.50 | 18.00 ~ 20.00 | 0.10 | |||||||||||||||||||||||||||

| I-S30403 | 022Cr19Nil0 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 8.00~ 12.00 | 18.00 ~ 20.00 | 一 | 一 | 一 | |||||||||||||||||||||||||

| I-S30409 | 07Cr19Ni10 | 0.04~0.10 | 0.75 | 2.00 | 0.035 | 0.020 | 8.00~ 10.50 | 18.00 ~ 20.00 | 一 | |||||||||||||||||||||||||||

| $31008 | 06Cr25Ni20 | 0.04~ 0.08 | 1.50 | 2.00 | 0.035 | 0.020 | 19.00 ~ 22.00 | 24.00 ~ 26.00 | ||||||||||||||||||||||||||||

| I-S31608 | 06Cr17Ni12Mo2 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00 ~ 14.00 | 16.00 ~ 18.00 | 2.00~ 3.00 | 0.10 | 一 | |||||||||||||||||||||||||

| I-S31603 | 022Cr17Ni12Mo2 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00 ~ 14.00 | 16.00 ~ 18.00 | 2.00-3.00 | 0.10 | 一 | |||||||||||||||||||||||||

| I-S31668 | 06Cr17Ni12Mo2Ti | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00 ~ 14.00 | 16.00 ~ 18.00 | 2.00~ 3.00 | 一 | 一 | I-Ti≥5C | ||||||||||||||||||||||||

| I-S39042 | 015Cr21M26Mo5Cu2 | 0.020 | 1.00 | 2.00 | 0.030 | 0.010 | 24,00~ 26.00 | 19.00 ~ 21.00 | 4.00~5.00 | 0.10 | 1.20~2.00 | 一 | ||||||||||||||||||||||||

| I-S31708 | 06Cr19Ni13Mo3 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 11.00 ~ 15.00 | 18.00 ~ 20.00 | 3.00~4.00 | 0.10 | 一 | 一 | ||||||||||||||||||||||||

| I-S31703 | 022Cr19Ni13Mo3 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 11.00 ~ 15.00 | 18.00 ~ 20.00 | 3.00~ 4.00 | 一 | ||||||||||||||||||||||||||

| I-S32168 | 06Cr18Nil1Ti | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 9.00 ~ 12.00 | 17.0 ~ 19.00 | I-Ti≥5C | |||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||

| I-GB/T 20878 | Ikhodi yenombolo ehlanganisiwe | Ibhrendi | Ukwakheka kwamakhemikhali (ingxenyana yobuningi)/% | |||||||||||||||||||||||||||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N | Okunye | ||||||||||||||||||||||||||

| 68 | S21953 | 022Cr19Ni5Mo3S2N | 0.030 | 1.30 ~ 2.00 | 1.00~ 2.00 | 0.030 | 0.020 | 18.00~19.50 | 4.50 ~ 5.50 | 2.50~ 3.00 | 一 | 0.05~ 0.12 | 一 | |||||||||||||||||||||||

| 70 | S22253 | 022Cr22Ni5Mo3N | 0.030 | 1.00 | 2.00 | 0.030 | 0.020 | 21.00 ~ 23.00 | 4.50~ 6.50 | 2.50~ 3.50 | 0.08~ 0.20 | 一 | ||||||||||||||||||||||||

| 71 | I-S22053 | 022Cr23Ni5Mo3N | 0.030 | 1.00 | 2.00 | 0.030 | 0.020 | 22.00 ~ 23.00 | 4.50~ 6.50 | 3.00~ 3.50 | 一 | 0.14~ 0.20 | 一 | |||||||||||||||||||||||

| Ukwakheka kwamakhemikhali kwamanye amabhrendi etafuleni kuhlukile kulokho kwe-GB/T 20878 | ||||||||||||||||||||||||||||||||||||

| I-GB/T 20878 | Ikhodi yokufundisa ehlanganisiwe | Ibhrendi | Ukwakheka kwamakhemikhali (ingxenyana yobuningi)/% | |||||||||||||||||||||||||||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | N | Okunye | |||||||||||||||||||||||||||

| 78 | I-S11348 | 96C-13A | 0.08 | 1.00 | 1.00 | 0.035 | 0.020 | 11.50 ~ 14.50 | 0.60 | - | - | I-Al:0.10~ 0.30 | ||||||||||||||||||||||||

| 92 | I-S11972 | 019Cr19Mo2NbTi | 0.025 | 1.00 | 1.00 | 0.035 | 0.020 | 17.50 ~ 19.50 | 1.00 | 1.75~2.50 | 0.035 | (Ti+Nb) [0.20+4 (C+N)] ~0.80 | ||||||||||||||||||||||||

| 97 | I-S11306 | 06Cr13 | 0.06 | 1.00 | 1.00 | 0.035 | 0.020 | 11.50~13.50 | 0.60 | 一 | 一 | |||||||||||||||||||||||||

| Ukwakheka kwamakhemikhali kwamanye amabhrendi etafuleni kuhlukile kulokho kwe-GB/T 20878 | ||||||||||||||||||||||||||||||||||||

Ukuqina Okujwayelekile

Ububanzi bepuleti lensimbi engagqwali:

1000mm, 1220mm, 1250mm, 1500mm, 1800mm, 2000mm.

Non-plate ubude: 1000mm, 1220mm, 1250mm, 1500mm, 1800mm, 2000mm bunganqunywa ngokuvumelana nezidingo zamakhasimende.

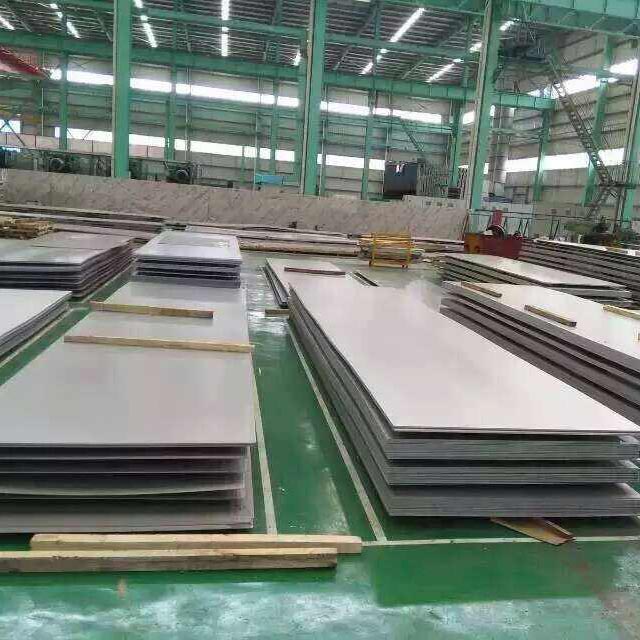

Isigaba sokugoqa esibandayo:

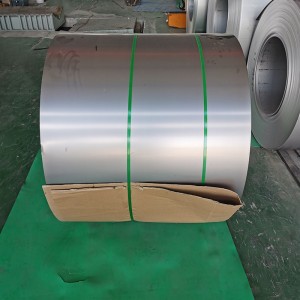

Ipuleti lensimbi engagqwali eligoqiwe elibandayo elingu-2B (ikhoyili, umucu, ipuleti eliyisicaba) ipuleti lesici: 3 5mm—6mm 304/2B, 316L/2B.

Ubukhulu: kubanda kugoqeke 2B (0.1-6.0mm).

Ubuso: 2B indawo ebushelelezi, BA.

8K isibuko;Ukudweba ngocingo kanye nesihlabathi;Isihlabathi seqhwa;Ipuleti lensimbi engenazigxivizo zeminwe.

Iphaneli yokuhlobisa: ipuleti lombala, ipuleti le-titanium, i-etching plate, ipuleti lezinwele ezipholisha uwoyela (HL, NO.4), ipuleti le-3D elinezinhlangothi ezintathu, ipuleti le-sandblasting, ipuleti elinamathiselwe.

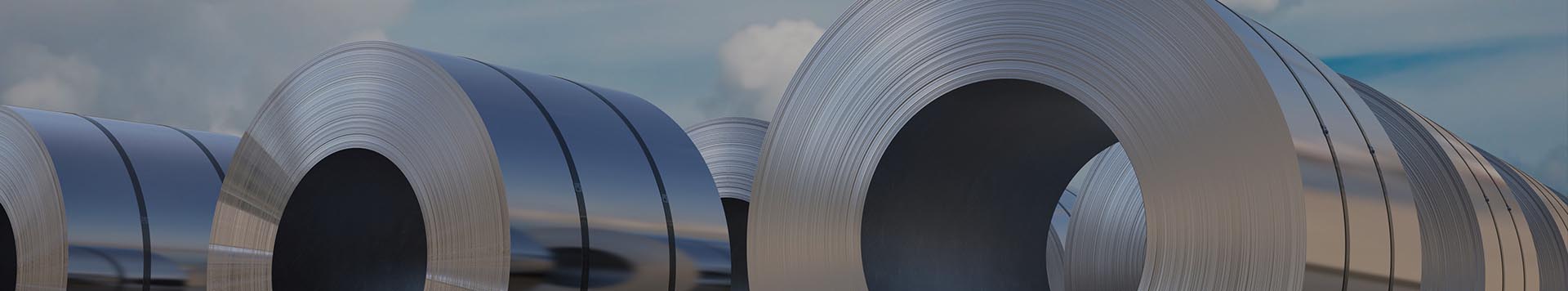

Umnyango wokugoqa oshisayo: ipuleti lensimbi engagqwali elishisayo eligoqayo elinguNo.1 (ikhoyili, ipuleti eliyisicaba).

Ubukhulu: yezimboni No.1 (3-159mm).

Ubuso: Isibuko esingu-8K;Ukudweba ngocingo, i-titanium plating, i-sanding;Isihlabathi seqhwa;Ipuleti lensimbi engenazigxivizo zeminwe.