Okuthandwayo okushisayo kwe-dip galvanized strip steel

Inqubo Yokukhiqiza

Isigaba I

Ikhoyili yonke ye-strip steel izovuthwa futhi ingcoliswe ukuze kufinyelele indawo ekhanyayo futhi ehlanzekile.

Isigaba II

1.I-Hot-dip galvanizing: ngemva kokukhetha, ihlanzwa nge-ammonium chloride noma i-zinc chloride isixazululo samanzi noma i-ammonium chloride ne-zinc chloride exutshwe nethangi lesisombululo samanzi. Bese ithunyelwa ethangini lediphu elishisayo ukuze lifakwe uthayela.

2.I-Hot galvanizing: ngemva kokukhetha, ihlanzwa kubhavu we-ammonium chloride noma i-zinc chloride isixazululo samanzi noma i-ammonium chloride ne-zinc chloride exutshwe nesisombululo esinamanzi, bese ithunyelwa kubhavu wokuvuza emva kwesithando somlilo esiqhubekayo sokuvuthwa.

3.I-galvanizing eqondile: ngemva kokukhetha, ithunyelwa esithandweni somlilo esiqhubekayo bese ingena ethangini elifaka uthayela ukuze livuthe.

Isigaba III

Ngemuva kokuthi insimbi ye-strip isiphehliwe, kufanele ihlanganiswe futhi ifakwe endaweni yokugcina. Isendlalelo esinothayela akufanele sibe ngaphansi kuka-50g/m2 ngokwezidingo zekhasimende, futhi noma iyiphi isampula akufanele ibe ngaphansi kuka-48g/m2.

Insimbi eyi-galvanized strip ngokuvamile isetshenziselwa ukwenza amapayipi ensimbi, njengamapayipi abamba ukushisa, amapayipi amanzi okuphuza, amapayipi okufudumeza, namapayipi ahambisa igesi; Ingasetshenziswa nakwezokwakha, embonini ekhanyayo, ezezimoto, ezolimo, ezemfuyo, ezokudoba, ezentengiselwano nezinye izimboni.

Umucu wensimbi ophehliwe ukhombisa ukuthi imboni yezokwakha isetshenziselwa ikakhulukazi ukwakha amaphaneli ophahleni lwezakhiwo ezilwa nokugqwala, amagridi ophahleni, njll; Imboni yokukhanya iyisebenzisela ukwenza amagobolondo ezinto zikagesi zasendlini, oshimula bomphakathi, izitsha zasekhishini, njll., futhi imboni yezimoto iyisebenzisela kakhulu ukwakha izingxenye zezimoto ezimelana nokugqwala, njll; Ezolimo, ukufuywa kwezilwane kanye nezokudoba kusetshenziswa kakhulu njengendawo yokugcina ukudla kanye nokuthutha, amathuluzi okucubungula eqandisiwe enyama nemikhiqizo yasemanzini, njll; Ngokwezentengiselwano, isetshenziswa ikakhulukazi njengendawo yokugcina, ezokuthutha kanye nemishini yokupakisha; Ibha yesakhiwo sensimbi ye-sandalwood (insimbi emise okwe-C, Z); Insimbi elula, i-ceiling keel, njll.

Ukuchezuka kokuqina okuvumelekile

| Amandla esivuno esincaneMpa | Ukujiya okuzisholomm | Ukuchezuka kokuqina okuvumelekile | UkunembaPT.A | Ukunemba okuphezuluPT.B | Ububanzi begama | ≤1200 | >1200-≤1500 | > 1500 | ≤1200 | 1200-≤1500 |

| <280 | s0.40 | ±0.05 | ±0.06 | ±0.03 | ±0.04 | |||||

| >0.40-0.60 | ±0.06 | ±0.07 | ±0.08 | ±0.04 | ±0.05 | |||||

| >0.60-0.80 | ±0.07 | ±0.08 | ±0.09 | ±0.05 | ±0.06 | |||||

| >0.80-1.00 | ±0.08 | ±0.09 | ±0.10 | ±0.06 | ±0.07 | |||||

| >1.00-1.20 | ±0.09 | ±0.10 | ±0.11 | ±0.07 | ±0.08 | |||||

| >1.20-1.60 | ±0.11 | ±0.12 | ±0.12 | ±0.08 | ±0.09 | |||||

| > 1.60-2.00 | ±0.13 | ±0.14 | ±0.14 | ±0.09 | ±0.10 | |||||

| > 2.00-2.50 | ±0.15 | ±0.16 | ±0.16 | ±0.11 | ±0.12 | |||||

| >2.50-3.00 | ±0.17 | ±0.18 | ±0.18 | ±0.12 | ±0.13 | |||||

| ≥280 | ≤0.40 | ±0.06 | ±0.07 | ±0.04 | ±0.05 | |||||

| >0.40-0.60 | ±0.07 | ±0.08 | ±0.09 | ±0.05 | ±0.06 | |||||

| >0.60-0.80 | ±0.08 | ±0.09 | ±0.11 | ±0.06 | ±0.06 | |||||

| >0.80-1.00 | ±0.09 | ±0.11 | ±0.12 | ±0.07 | ±0.08 | |||||

| >1.00-1.20 | ±0.11 | ±0.12 | ±0.13 | ±0.08 | ±0.09 | |||||

| >1.20-1.60 | ±0.13 | ±0.14 | ±0.14 | ±0.09 | ±0.11 | |||||

| > 1.60-2.00 | ±0.15 | ±0.17 | ±0.17 | ±0.11 | ±0.12 | |||||

| > 2.00-2.50 | ±0.18 | ±0.19 | ±0.19 | ±0.13 | ±0.14 | |||||

| >2.50-3.00 | ±0.20 | ±0.21 | ±0.21 | ±0.14 | ±0.15 |

| Ububanzi begama mm | Ukuchezuka kobubanzi obuvumelekile (mm) | Ukunemba okuvamile PW.A | Ukunemba okuthuthukile PW.B | Inani elincane | Ubuningi | Inani elincane | Ubuningi |

| 2600-1200 | 0 | +5 | 0 | +2 | |||

| 1200-1500 | 0 | +6 | 0 | +2 | |||

| > 1500 | 0 | +7 | 0 | +3 | |||

| Ukuchezuka okuvunyelwe kobude | |||||||

| Ubude begama mm | Ukuchezuka okuvumelekile kobude (mm) | Ukunemba okujwayelekile PL.A | Ukunemba okuthuthukisiwe kwe-PL.B | Inani elincane | Ubuningi | Inani elincane | Ubuningi |

| =2000 | 0 | +6 | 0 | +3 | |||

| ≥2000 | 0 | Ubude 0.3% | 0 | Ubude obungu-0.15% | |||

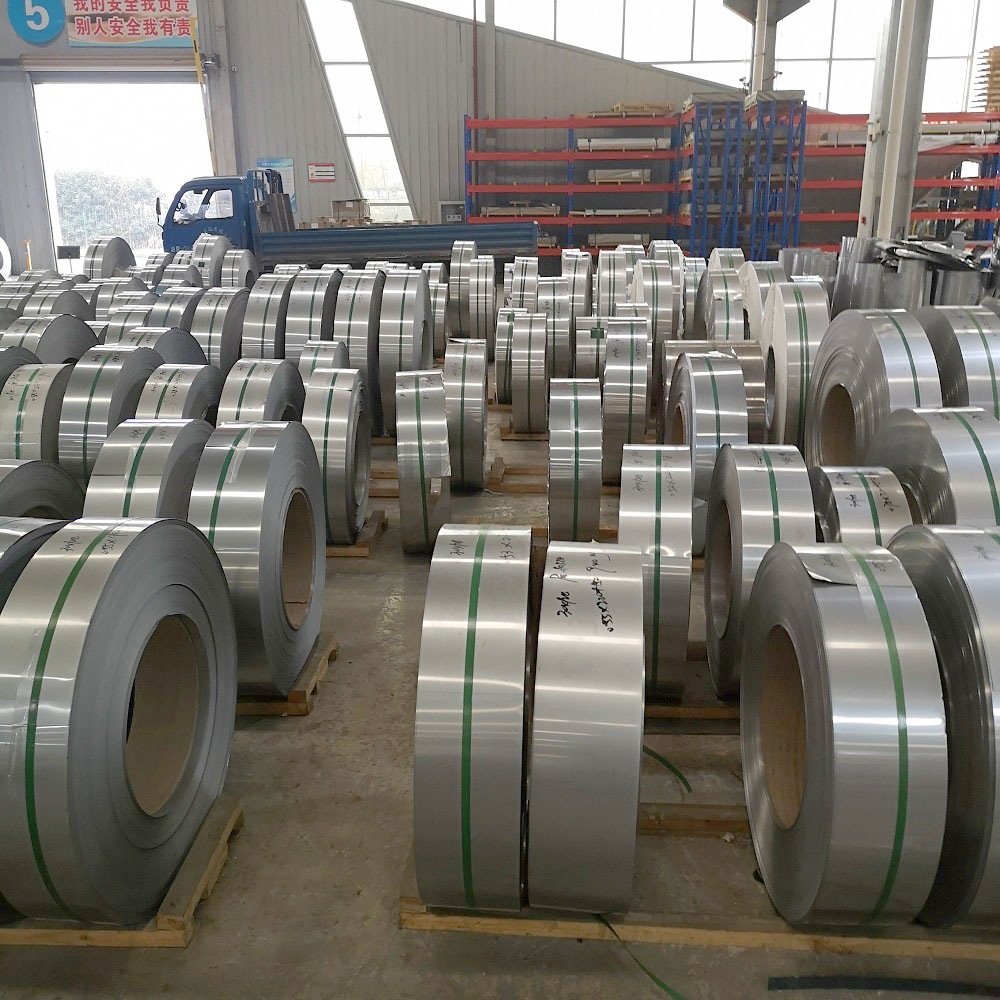

Ukusetshenziswa Komucu Wensimbi

Insimbi eyi-galvanized strip ngokuvamile isetshenziselwa ukwenza amapayipi ensimbi, njengamapayipi abamba ukushisa, amapayipi amanzi okuphuza, amapayipi okufudumeza, namapayipi ahambisa igesi; Ingasetshenziswa nakwezokwakha, embonini ekhanyayo, ezezimoto, ezolimo, ezemfuyo, ezokudoba, ezentengiselwano nezinye izimboni. Imboni yezokwakha isetshenziselwa ikakhulukazi ukwakha amaphaneli ophahleni lwezakhiwo ezilwa nokugqwala, ama-roof grids, njll; Imboni yokukhanya iyisebenzisela ukwenza amagobolondo ezinto zikagesi zasendlini, oshimula bomphakathi, izitsha zasekhishini, njll., futhi imboni yezimoto iyisebenzisela kakhulu ukwakha izingxenye zezimoto ezimelana nokugqwala, njll; Ezolimo, ukufuywa kwezilwane kanye nezokudoba kusetshenziswa kakhulu njengendawo yokugcina ukudla kanye nokuthutha, amathuluzi okucubungula eqandisiwe enyama nemikhiqizo yasemanzini, njll; Ngokwezentengiselwano, isetshenziswa ikakhulukazi njengendawo yokugcina, ezokuthutha kanye nemishini yokupakisha; Ibha yesakhiwo sensimbi ye-sandalwood (insimbi emise okwe-C, Z); Insimbi elula, i-ceiling keel, njll.

Izici zomugqa wensimbi: umugqa wensimbi uwuhlobo lwempahla eluhlaza ebizwa ngokuthi (zinc) embozwa epuletini lensimbi elide nelincane eligoqekayo elibandayo noma eligoqekayo elishisayo. I-galvanizing eshisayo inezinzuzo zokugqoka okufanayo, ukunamathela okuqinile nokuphila isikhathi eside. Ukusabela okuyinkimbinkimbi ngokomzimba namakhemikhali phakathi kwepayipi elishisayo lensimbi ecwilisiwe kanye nesisombululo sokucwenga esincibilikisiwe kwenza ungqimba lwengxubevange ye-zinc-iron olungagqwali olunesakhiwo esihlangene. I-alloy layer ihlanganiswe ne-zin c ehlanzekile kanye ne-strip steel substrate. Ngakho-ke, inokumelana nokugqwala okuqinile. Amaphuzu ekhwalithi ensimbi ewuhlaka oluthathiwe azoba bushelelezi ngokubukeka, angabi namaqhuqhuva e-zinc nama-burrs, futhi abe mhlophe okuyisiliva; Ubukhulu buyalawuleka, phakathi kuka-5-107 μ Noma yikuphi ukukhetha ngaphakathi kwe-m; Ayikho i-hydrogen embrittlement kanye nengozi yokushisa, engaqinisekisa ukuthi izakhiwo zemishini yezinto ezibonakalayo zihlala zingashintshiwe; Ingathatha indawo yezinqubo ezithile ezidinga ukuvuthwa okushisayo; Ukumelana nokugqwala okuhle, ukuhlolwa kwesifutho sikasawoti okungathathi hlangothi kuze kufike emahoreni angama-240; Etc. Strip steel, eyaziwa nangokuthi i-steel strip, ingaphakathi kuka-1300mm ububanzi, futhi ubude bayo buhluke kancane ngokobukhulu bekhoyili ngayinye. I-strip steel ngokuvamile inikezwa ngamakhoyili, anezinzuzo zokunemba kobukhulu obuphezulu, ikhwalithi ephezulu yendawo, ukucubungula kalula nokonga impahla.

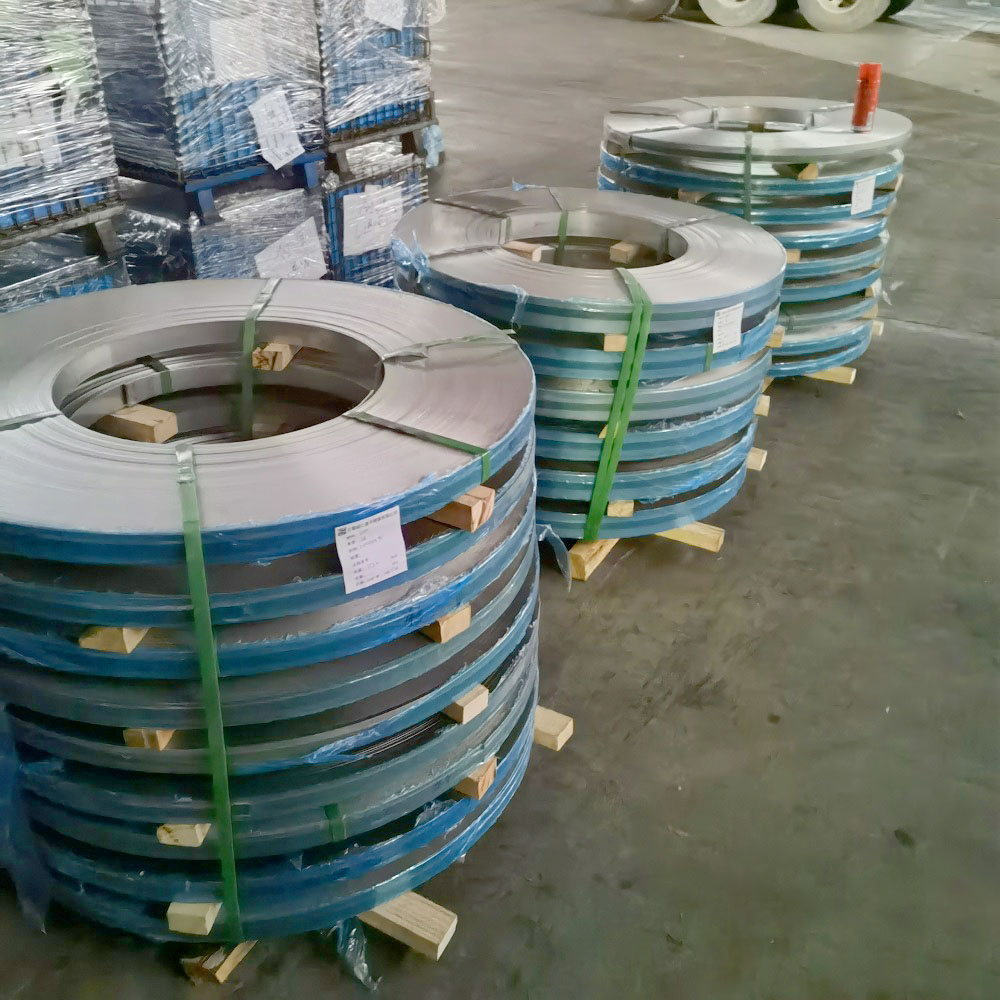

Indlela yokupakisha: inqwaba, ikesi lezinkuni

Imodi yokuthekelisa: ezokuthutha ngemoto

Imininingwane Umdwebo